DEVELOPMENTS

Keeping Essential Food Businesses Open During the COVID-19 Crisis in Afghanistan

Mar 15, 2021

COVID-19 has disrupted the way industries operate globally. Remaining commercially viable in the face of supply and demand shocks, while safeguarding workers, has been challenging for all businesses. In the low- and middle-income countries where DAI operates, the situation is even more severe because the reach of public emergency support to businesses—in the form of loans, credits, tax relief, and financial support to pay wages—is often limited.

In Afghanistan, where DAI implements the Regional Agricultural Development Program in the East (RADP-East) project, food businesses are facing liquidity shortages and laying off workers. According to the U.S. Agency for International Development (USAID)-commissioned COVID-19 Business Pulse Survey, conducted by the International Finance Corporation and World Bank, the average business in Afghanistan signaled, in September 2020, that it may struggle to operate beyond two more months.

Considering these trends, keeping essential businesses open while mitigating transmission risks at the workplace is a priority task for governments and donors alike. At the onset of the pandemic, RADP-East took on this task and swiftly commissioned COVID-19 mitigation training videos that were informed by science-based content and industry-specific best practices to help firms reduce transmission risk in the workplace. In close collaboration with Afghan food processing firms, the project adapted industry best practices, example measures from other businesses, to company scale and local context, packaging tailored videos in easily digestible and virtual forms to help small business owners modify their operations and safeguard workers and clients.

Below, we present the steps taken to develop these training videos and the important lessons learned along the way.

Sourcing Content

RADP-East targeted dairy, poultry, dried fruit, jam, and tomato processors; fresh fruit and vegetable packers; retail poultry butcher shops; and retail dairy outlets as beneficiaries of the COVID-19 mitigation training videos. Small and medium-sized businesses in these value chains are essential to daily food production and distribution; employ substantial numbers of people, usually working in close proximity to one another; and have daily contact with farmers, suppliers, transporters, and customers.

Gathering and validating the content for these videos involved identifying industry-specific, COVID-19 mitigation measures employed to keep food businesses open in other countries; liaising with food processing companies and industry experts; researching public and university COVID-19 information sites; and attentively sampling the evolving ecosystem of industry efforts to mitigate and adapt to COVID-19. RADP-East also drew from DAI’s internal task force and project efforts to source industry-specific mitigation measures backed by science. Ultimately, more than 40 health and industry-specific sites—including associations representing diverse memberships, from agribusiness to community agriculture groups—and 42 companies were consulted.

RADP-East also leveraged the power of social media to crowdsource examples of different types and scales of adaptation measures. The list below shows a portion of the core resource sites referenced. From March through August, the project triangulated information from these sources, updating its analysis weekly to stay abreast of the rapidly changing COVID-19 science and its application by industries. The team then filtered the information retrieved, adapting it to the conditions facing the Afghan worker and Afghan value chains through cooperation with the Afghan firms. General guidelines from public health officials were translated into practical, industry-specific communication points for company staff.

- Occupational Safety and Health Administration

- Food and Drug Administration

- Centers for Disease Control and Prevention

- Cornell University’s College of Agriculture and Life Sciences

- World Health Organization

- Environmental Protection Agency

- United States Department of Agriculture

- Consumer Brands Association

- The Packer

- Food Processing

- International Foodservice Distributors Association

- The Food Institute

- National Restaurant Association

Tailoring Training for Specific Industries

Developing the training materials was a five-month effort that involved sourcing footage from private and public sources, scripting, and producing English voiceovers for each video. The modules took the form of webinar-style trainings developed from storyboards, with some footage from Lebanese processors who were early adopters of good virus mitigation practices. This training was translated into Dari and Pashto. The video training provided managers with actionable COVID-19 mitigation techniques that can be implemented in the workplace.

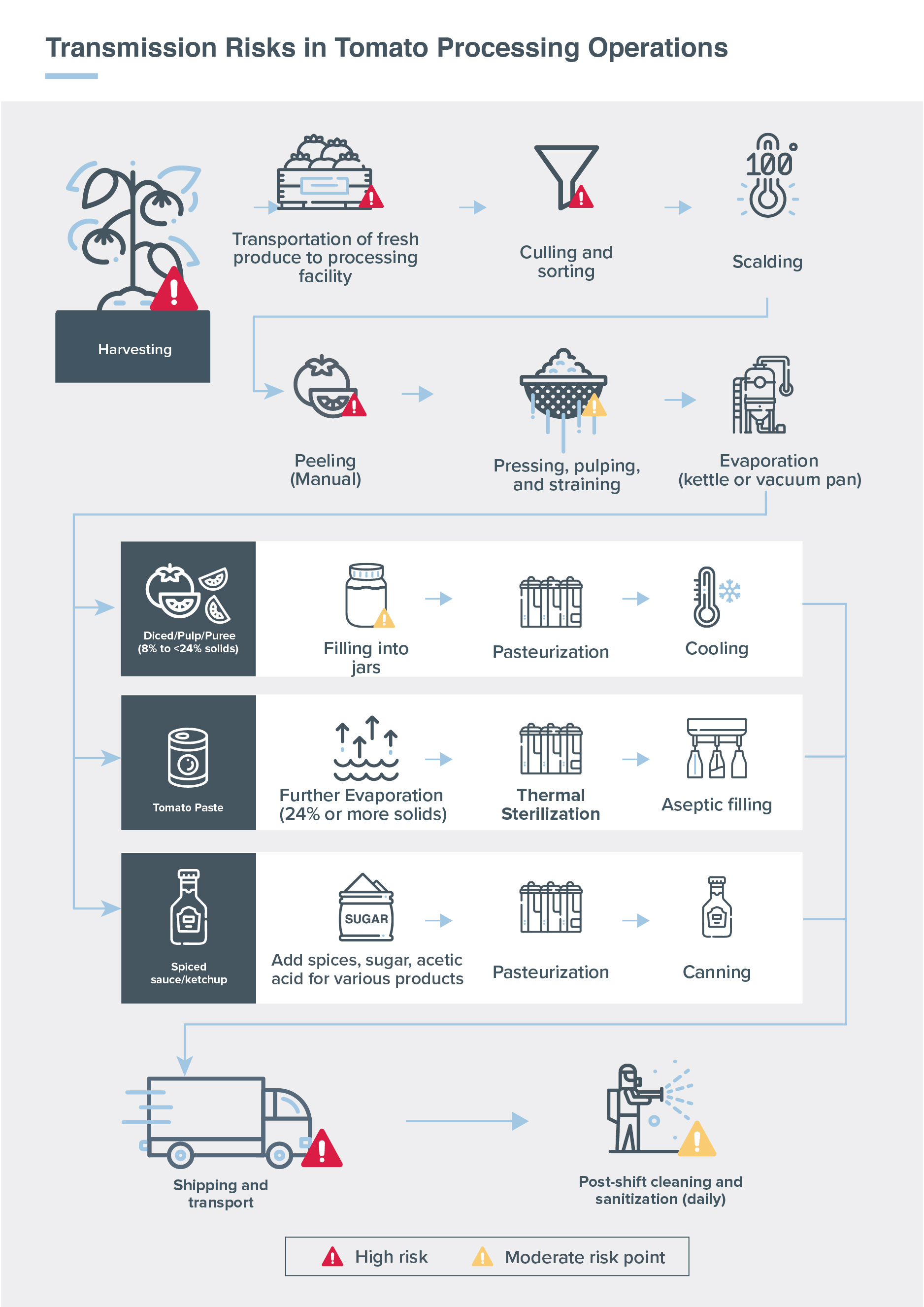

The messages and accompanying graphics, footage, and pictures of COVID-19 mitigation measures center on precautions owners, managers, and workers should take to reduce the risk of exposure to themselves, their customers, and their suppliers. Accordingly, the videos highlight facilities and equipment layouts, worker organization, raw material supply chains, distribution channels, and retail operations that present exposure risk. The training emphasizes that identifying these high-risk points in worker-supplier, worker-worker, and worker-customer interactions is critically important for reducing the risk of transmission. The videos provide concrete recommendations for measures to mitigate transmission at each high-risk point.

“I had no information on food safety and COVID-19 mitigation measures before the training,” said one participant. “My shop was unorganized, and I was not implementing the mitigation measures. After the training, I am now using personal protective equipment, and I brought required modifications in my shop which now attracts more buyers.”

Atiqullah, a dairy shop owner, shared similar sentiments: “After receiving COVID-19 mitigation training, I brought a lot of changes to my shop and in my operation. I use masks, gloves, shoe net, and hairnet, and by doing so, I feel protected from COVID-19 and my customers also feel good.”

Thanks to these trainings, at least 119 Afghan food businesses have been able to easily identify high-risk points in their operations and put in place risk control measures to minimize workers’ and clients’ exposure to COVID-19, thereby keeping businesses open. Feedback from retailers suggests that firms needed to see both a safety and a business reason to adopt changes in their operations. Staying open is of course a good business reason; being perceived as concerned for clients’ health and actively implementing mitigation measures is also a competitive advantage.

The COVID-19 mitigation measures are certainly accruing positive returns; one dairy retail shop observed a 63 percent increase in sales compared to four months ago. Shop owners attribute their increased profits to the improved hygiene and COVID-19 mitigation measures practiced by staff, which reassures both workers and customers concerned about safety.

While the video trainings were created for essential food businesses in Afghanistan, the videos have broader applications and can be adapted to specific country, worker, and value chain contexts. USAID projects in Ukraine and Rwanda, for example, are gauging the possibility of adapting these trainings to their local circumstances. These video trainings present a replicable model that practitioners can adopt to help enterprises mitigate transmission risks and be more resilient in the face of COVID-19.

An employee serves customers fresh, cooled yogurt from a new refrigerator. He received training in COVID-19 food safety, personal hygiene, and improved technology as well as a refrigerated display case in a cost-sharing grant for the firm's dairy products under a RADP-East grant.

Lessons and Opportunities for Practitioners

While an effective response to COVID-19 requires new and innovative solutions, adherence to some of the “evergreen” principles of effective development will optimize lasting results. RADP-East focused intently on localizing solutions, for example. As part of the material development process, the project team consulted directly with Afghan firms on the applicability of some of the mitigating measures implemented by various firms: plexiglass shields at cash counters, for example, moving sales to “at-the-curb” delivery, cash trays used to avoid contact where digital payments simply don’t exist, among others.

The project introduced such measures to Afghan firms as ideas ahead of the training delivery, and only the ones endorsed by the firms were included in the training videos. Even though the urgency of the disease response might have made it tempting to bypass this collaborative approach, RADP-East’s partner-led co-creation process ensured that the proposed solutions would address the current reality of businesses and lead to a more favorable reception, better utility, and, ultimately, greater sustainability.

RADP-East’s quest for truly applicable solutions also meant pivoting from working with U.S. firms to instead tapping Lebanese firms for the best footage of adaptive measures being implemented. Originally, the team solicited U.S. and international firms for video footage of operational changes they were making in the workplace. The plan was to use this footage, complemented by materials from public resources and social media videos in the public domain. However, liability concerns—including fear of lawsuits and uncertainty about anonymity during the first wave of COVID-19—led almost all of the U.S. firms to decline citation, and they were reluctant to provide video of their adaptation efforts beyond what was already public.

Not to be deterred, the project turned to processors in Lebanon with which DAI, through its now-closed Lebanon Industry Value Chain Development project, had worked to draw example footage on how Lebanese firms were modifying their operations. Ultimately this approach proved more effective. The Lebanese firms had greater similarities in products, facility scale, and workforce to firms in Afghanistan, and they were open to on-camera interviews, photography, and filming.

This and other examples illustrate the crucial need for agility and a willingness to rapidly adapt in a context where information from reliable sources is not always forthcoming. Since COVID-19 was a novel virus, national and international health institutions struggled to reach unanimity on the most effective measures to stop the spread. For example, delays in the release of recommendations on masking protocols and conflicting guidance on social distancing hindered information exchange on effective adaptive measures. As a result, the team needed to remain agile, adapt quickly, and triangulate information to provide guidance backed by published science.

One suggestion for development practitioners, when dealing with novel disease shocks, is to leverage the untapped potential of new techniques and technology, such as artificial intelligence, to speed up the process of identifying mitigation options—options that are corroborated by evidence from health bodies and have been tested by industry—to ensure the project’s interventions do not lag during the linear growth phase of viral spread.

RADP-East implemented a large-scale training program on tomato paste and ketchup production for home-based women entrepreneurs. With home-based firms, COVID-19 safety measures are tougher to enforce, and often only partially adopted.

Adaptable Strategies

As national governments continue to face fiscal pressure and tightening budgets due to the spread of the virus, RADP-East optimized its resources and expertise to bring together project staff, ministry cooperators, and small and medium-sized food processors and retailers to scope, iteratively design, and execute a COVID-19 response strategy that keeps essential businesses up and running while safeguarding workers and customers.

Drawing on the practical responses of international food industries facing the same pandemic threat, RADP-East iterated potential solutions on a weekly basis, triangulated these solutions with the evolving science on viral spread and infection in food industries, and engaged with food system companies to develop training materials that 119 Afghan companies are now using to navigate the immediate threats to the health and well-being of their mangers, essential workers, and customers.

These COVID-19 solutions and materials—along with the important lessons learned in putting them together—can be instructive for development practitioners seeking to assist similar industries in other countries, even as these countries work toward a longer-term solution based on vaccination and herd immunity.

Abdul Nasir, Deputy Chief of Party for RADP-East, contributed to this article.